Saponification System

Saponification system When utilizing oil and alkali for the saponification reaction, our company employs a high-temperature and high-pressure process to catalyze the reaction, ensuring complete

Saponification system When utilizing oil and alkali for the saponification reaction, our company employs a high-temperature and high-pressure process to catalyze the reaction, ensuring complete

Cooling & drying system The soap slurry, after complete saponification, is transformed into soap granules suitable for secondary processing in the production line through the

Syndent Bar System To achieve a standard production process and comply with modern hygiene and safety regulations, a powder-type interface activator and binder are utilized

Soap Finishing Line To achieve a standardized production process that complies with modern hygiene and safety regulations, fully saponified, colorless, and odorless soap noodles are

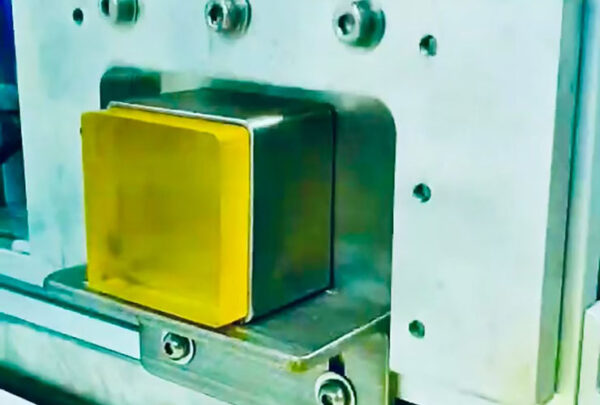

Transparent soap equipment In the saponification process, adding glycerin or alcohol and other alcohol-based additives allows for the orderly arrangement of soap molecules, imparting transparency

Cold process soap equipment Soap has evolved into various forms, with cold process soapmaking being one of the earliest and continuously used methods. In this